Japan’s Push for Ultra-Thin Solar Panels

Japan is making a significant investment in ultra-thin, flexible solar panels, aiming to meet its renewable energy goals and challenge China’s dominance in the sector. These pliable perovskite panels are particularly well-suited for Japan’s mountainous terrain, where flat land for traditional solar farms is scarce. A key component of these panels is iodine, a resource that Japan produces more of than any other country except Chile.

Despite the potential, the development of perovskite panels faces several challenges. They contain toxic lead, and currently, they generate less power and have shorter lifespans compared to silicon-based panels. However, with a goal of achieving net-zero emissions by 2050 and a desire to reduce reliance on Chinese solar technology, Japanese Minister of Industry Yoji Muto has called perovskite cells “our best card to achieve both decarbonisation and industrial competitiveness.”

The government is offering substantial incentives to encourage industry participation. For instance, a 157-billion-yen ($1 billion) subsidy has been allocated to Sekisui Chemical, a plastic manufacturer, to build a factory capable of producing enough perovskite solar panels to generate 100 megawatts by 2027. This amount of energy could power around 30,000 households.

By 2040, Japan aims to install enough perovskite panels to generate 20 gigawatts of electricity, equivalent to adding about 20 nuclear reactors. This initiative is expected to contribute significantly to Japan’s target of having renewable energy cover up to 50 percent of electricity demand by that year.

Breaking the Silicon Ceiling

Solar power, including both perovskite and silicon-based solar cells, is projected to cover up to 29 percent of all electricity demand by 2040, a sharp increase from 9.8 percent in 2023. Hiroshi Segawa, a specialist in next-generation solar technology at the University of Tokyo, emphasized the importance of utilizing all available technologies to achieve carbon neutrality.

Perovskite solar panels can be produced domestically, from raw materials to installation, which could enhance energy and economic security. Japan seeks to avoid repeating the boom and bust cycle of its previous solar business. In the early 2000s, Japanese-made silicon solar panels accounted for nearly half of the global market. Today, China controls over 80 percent of the global solar supply chain, from raw material production to module assembly.

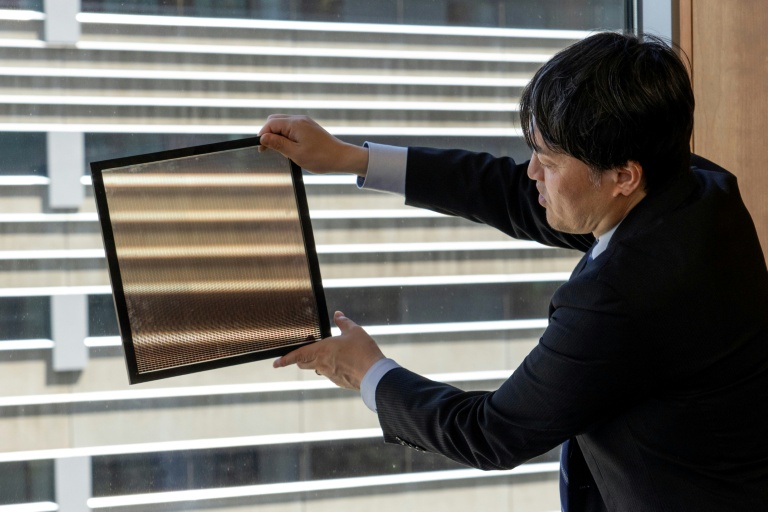

Silicon solar panels are made of thin wafers processed into cells that generate electricity. They require protection from reinforced glass sheets and metal frames, making them heavy and cumbersome. In contrast, perovskite solar cells are created by printing or painting ingredients such as iodine and lead onto surfaces like film or sheet glass. The final product can be just a millimeter thick and a tenth the weight of conventional silicon solar cells.

Generating Power Where It Is Used

The malleability of perovskite panels allows them to be installed on uneven and curved surfaces, an important feature in Japan, where 70 percent of the country is mountainous. These panels are already being incorporated into several projects, including a 46-story building in Tokyo set to be completed by 2028. The city of Fukuoka plans to cover a domed baseball stadium with perovskite panels, and major electronics brand Panasonic is working on integrating perovskite into windowpanes.

Yukihiro Kaneko, general manager of Panasonic’s perovskite PV development department, envisions a future where all windows have integrated solar cells. This would allow power to be generated where it is used, reducing the burden on the national grid.

Challenges and Future Prospects

Despite the enthusiasm, perovskite panels remain far from mass production. They are less efficient than their silicon counterparts and have a lifespan of only a decade, compared to 30 years for conventional units. The toxic lead they contain also requires careful disposal after use.

However, the technology is advancing rapidly. Some prototypes can perform nearly as powerfully as silicon panels, and their durability is expected to reach 20 years soon. Professor Segawa believes Japan could achieve a capacity of 40 gigawatts from perovskite by 2040, and the technology could also accelerate renewable energy adoption elsewhere.

“We should not think of it as either silicon or perovskite. We should look at how we can maximise our ability to utilise renewable energy,” Segawa said. He added that if Japan can demonstrate a successful model, it could be replicated overseas.